Sigma Mixer Vs Ribbon Mixer. At Wafaa sigma machines offer advantages homogeneous mixing, superior kneading, and efficient handling of high-viscosity materials, while minimizing shear and air incorporation.

Plodder In continuation from Sigma Mixer, WAFAA has refiner plodder which contributes significantly to texture refinement, blending, air bubble removal, dimensional consistency, quality assurance, production efficiency, and customization.

Roll Mill plays significant role in refining soap texture, controlling thickness, ensuring homogeneous blending, removing air bubbles, maintaining quality, enabling mass production, and allowing for customization and branding, all of which are essential for producing high-quality, visually appealing soap bars.

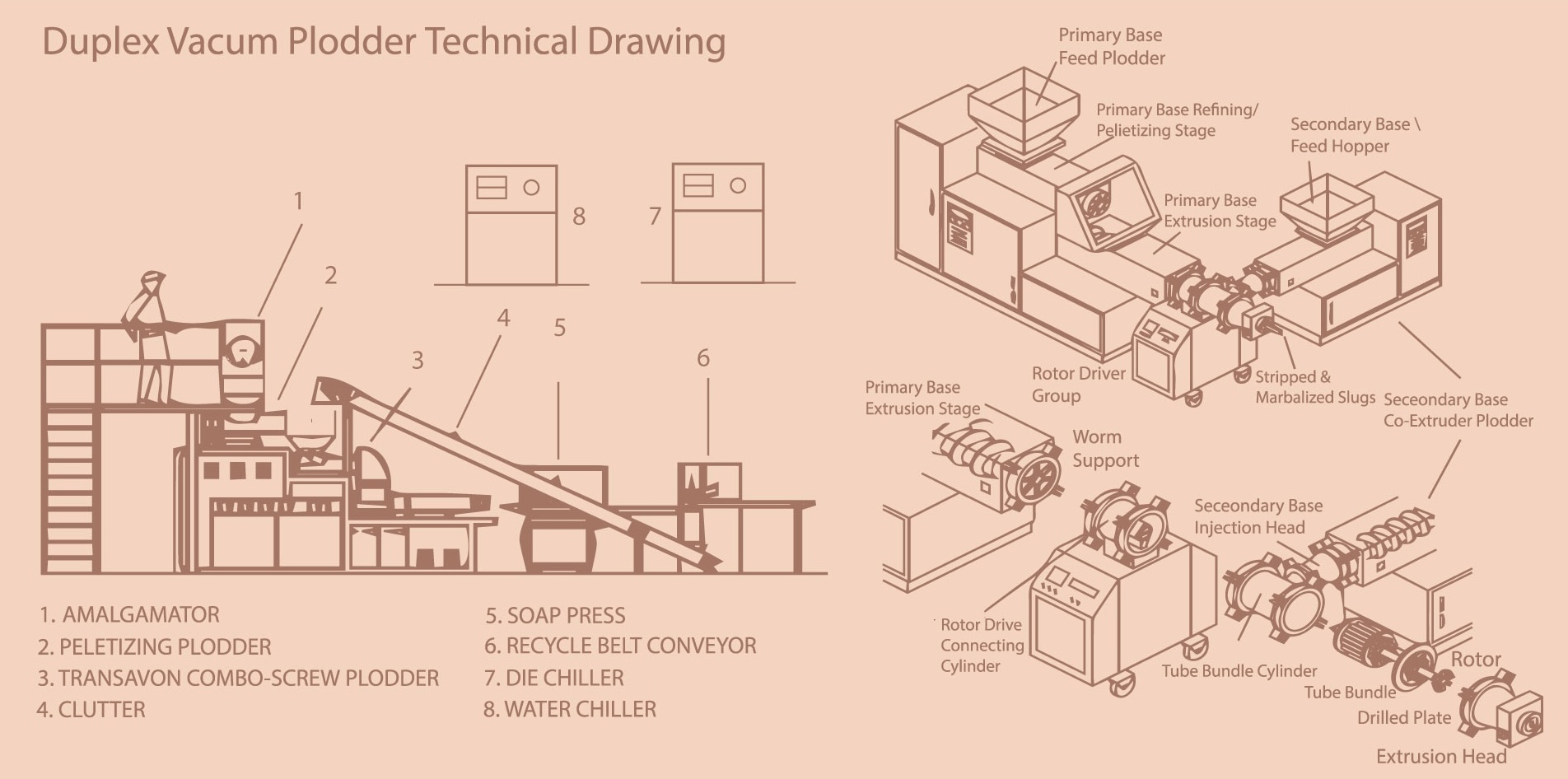

Duplex Vacuum Plodder

At WAFAA a pivotal machine in the soap bar manufacturing process is a Duplex Vacuum Plodder. This machine is meticulously designed to seamlessly convert milled soap flakes into the desired compact soap bars. The designation “Duplex” indicates its dual configuration, which usually involves two distinct stages for soap processing.

In the initial phase of the Duplex Vacuum Plodder, milled soap flakes are extruded. Following extrusion, the dense soap noodles are directed through a vacuum chamber, which serves to eliminate moisture, any entrapped air bubbles, or gases within the soap, performing vacuum cooling and drying thereby guaranteeing the creation of a flawlessly smooth and uniform textured soap bar. These compressed noodles subsequently proceed to the second plodder stage for further compaction.

Mazzoni Duplex stamper At, WAFAA stamper offers several advantages: increased production efficiency, precision, reduced labor costs, flexibility in design, and improved product aesthetics. These features make this machine a preferred choice for large-scale soap production when compared to ordinary soap bar stampers.

High-Quality Soap Bars at Scale

At WAFAA, we have harnessed our expertise, advanced production capabilities, and commitment to quality to become a leading manufacturer of soap bars.

Key Highlights of Our Soap Bar Manufacturing Capability:

Impressive Daily Output: Our factory has the capability to produce a substantial 10 MT of soap bars output each day. Achieved through streamlined and efficient production processes, allowing large-scale production requirements.

Diverse Product Range: Our soap production capability covers a diverse range of soap types, shapes, and sizes. Whether it’s standard soap bars, specialty bars, or soap with unique fragrances and formulations, we have the expertise and equipment to produce a wide variety of products.

Quality Assurance:

Consistency, Regulatory Compliance And Uniformity: WAFAA Quality Assurance Lab serves as the final checkpoint where rigorous tests and inspection are conducted of soap bars for any defects, irregularities, deviations from quality standards, regulatory requirements, including those related to ingredient labeling, safety, and hygiene. It helps to maintain the consistency, uniformity and performance criteria in every soap bar leaving the production line. Wafaa’s commitment to excellence, customer satisfaction, and continuous improvement, is a corner stone that contributes to the success and sustainability in the marketplace.